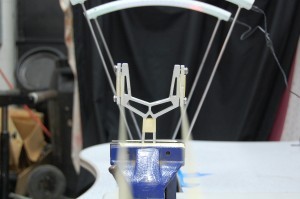

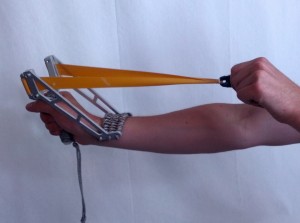

Jonathan bought a Y-Shot DIY kit and Iron Sights from us a while back. Before he bought he asked lots of questions to make sure this was the right purchase. After building the Y-Shot from the kit he shared his thoughts

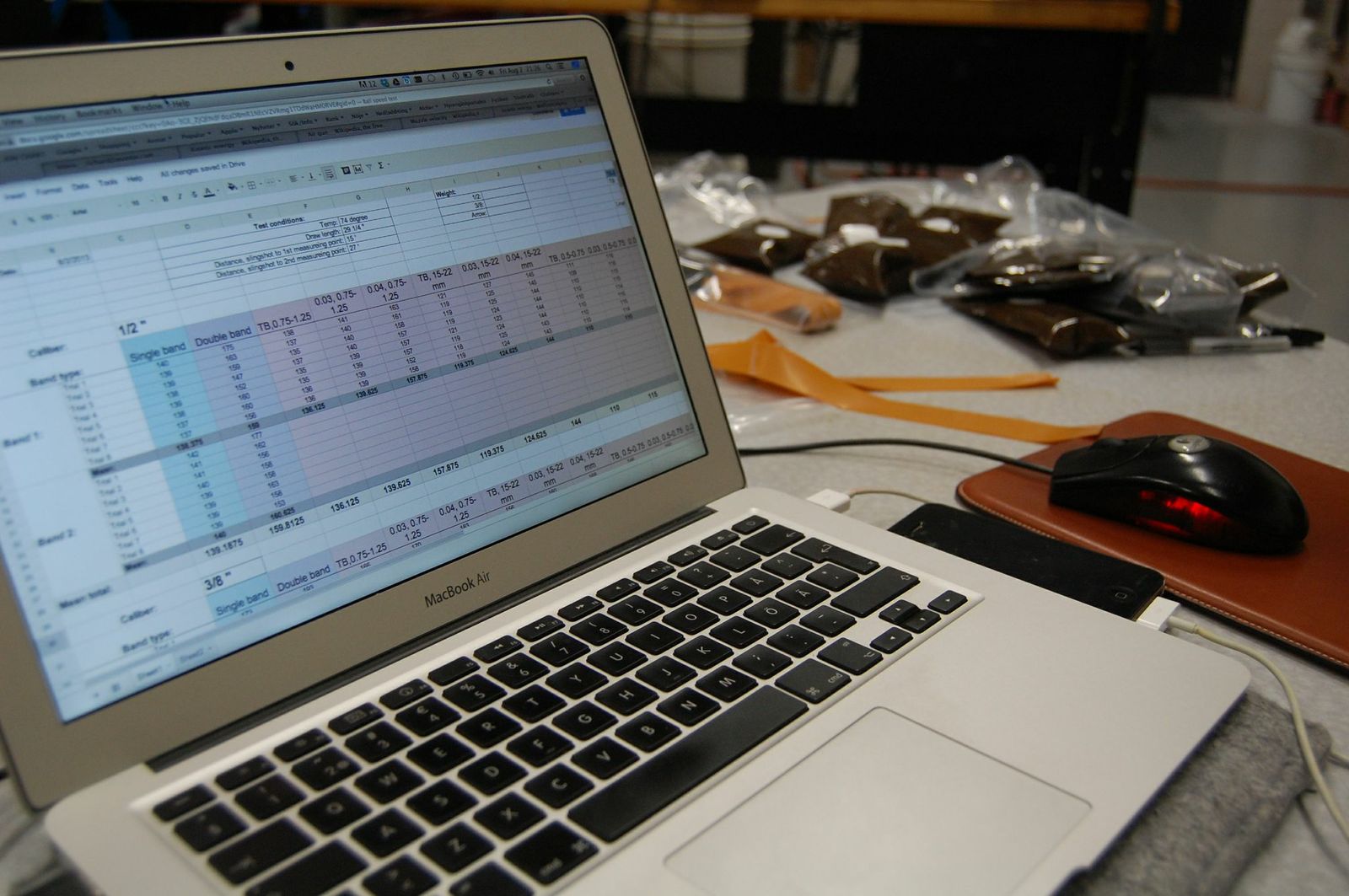

” A truly flexible item that combines target pistol accuracy if one chooses the iron sights (front and rear sight). Another innovative feature is that both tubular and flat bands can be used. In conclusion, the best part is versatility. To clarify versatility in this context means that you can learn sight alignment and reference points which is transferable for pistol shooting plus this item has the potential to rival an air pistol depending on the bands and projectile used.”

* The design actually prolongs the life of the bands

You can order the same parts

Jonathan’s Y-Shot

Jonathan’s Y-Shot

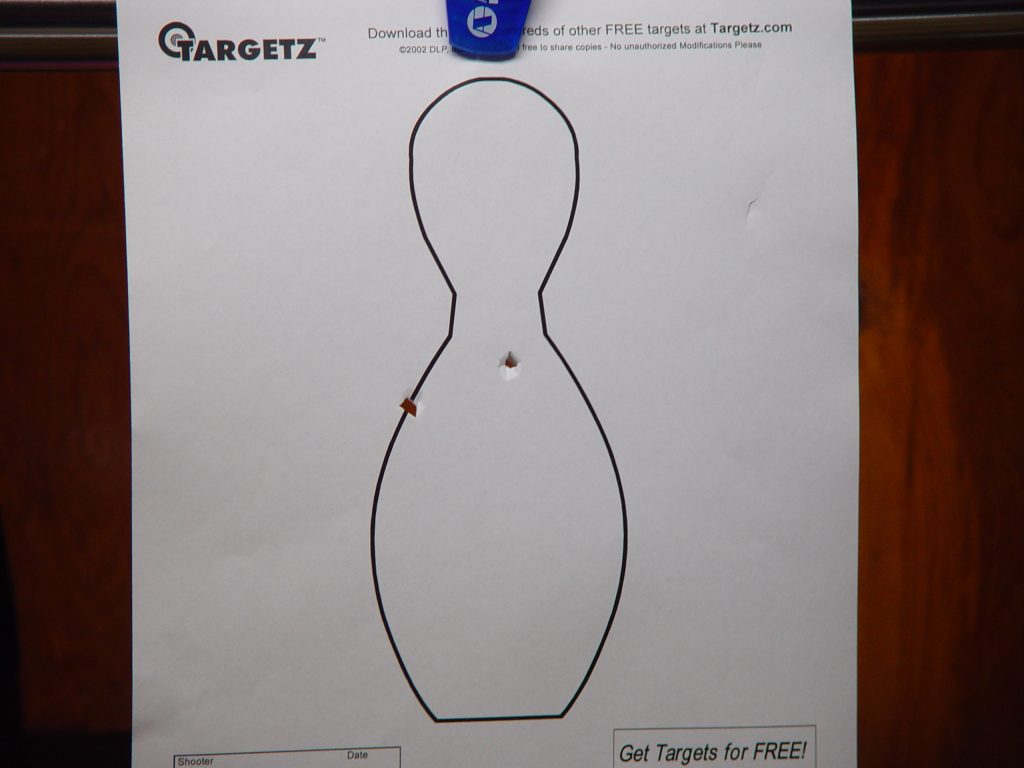

Jonathan also shared some targets with the results of his work.

Thanks for sharing these with us Jonathan!