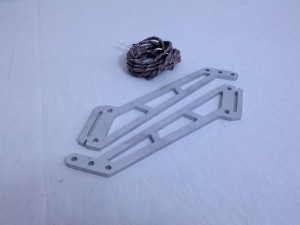

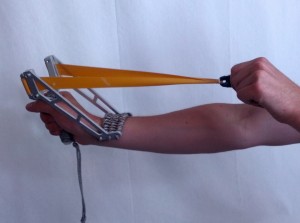

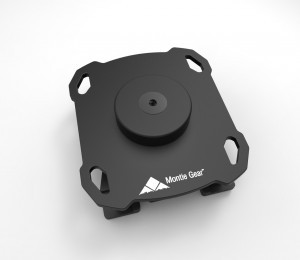

(Morrisville, N.C.) Collaborative product design and development firm Montie Design announces the availability of its unique portable shooting rest, the second original product conceived, designed, and distributed by the RTP-based company in the last nine months. Designed to meet the needs of all shooters as well as most firearms, the easy-to-carry rest weighs less than two pounds and disassembles easily in three pieces, fitting neatly into a small carrying case. Unlike conventional bench rests, which are heavy and complex, the novel Montie Design model — made of sturdy yet lightweight aluminum — provides steady support for different sized long guns ranging from semi-automatic and bolt action rifles to shotguns, carbines and pistols.

(Morrisville, N.C.) Collaborative product design and development firm Montie Design announces the availability of its unique portable shooting rest, the second original product conceived, designed, and distributed by the RTP-based company in the last nine months. Designed to meet the needs of all shooters as well as most firearms, the easy-to-carry rest weighs less than two pounds and disassembles easily in three pieces, fitting neatly into a small carrying case. Unlike conventional bench rests, which are heavy and complex, the novel Montie Design model — made of sturdy yet lightweight aluminum — provides steady support for different sized long guns ranging from semi-automatic and bolt action rifles to shotguns, carbines and pistols.

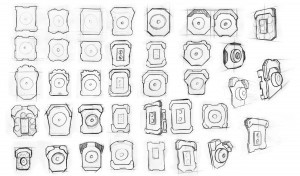

“There’s nothing like this on the market,” said Montie Roland, president of Montie Design and active shooting enthusiast. Roland, who used to shoot competitively and has a daughter on a local junior rifle team, said he got the idea for the product after tiring of carrying around a conventional combination of a heavy rest and sand bags for recreational shooting.

I realized that a lighter weight version would serve the recreational shooter better,?

Share on Facebook

(Morrisville, N.C.) Collaborative product design and development firm Montie Design announces the availability of its unique portable shooting rest, the second original product conceived, designed, and distributed by the RTP-based company in the last nine months. Designed to meet the needs of all shooters as well as most firearms, the easy-to-carry rest weighs less than two pounds and disassembles easily in three pieces, fitting neatly into a small carrying case. Unlike conventional bench rests, which are heavy and complex, the novel Montie Design model — made of sturdy yet lightweight aluminum — provides steady support for different sized long guns ranging from semi-automatic and bolt action rifles to shotguns, carbines and pistols.

(Morrisville, N.C.) Collaborative product design and development firm Montie Design announces the availability of its unique portable shooting rest, the second original product conceived, designed, and distributed by the RTP-based company in the last nine months. Designed to meet the needs of all shooters as well as most firearms, the easy-to-carry rest weighs less than two pounds and disassembles easily in three pieces, fitting neatly into a small carrying case. Unlike conventional bench rests, which are heavy and complex, the novel Montie Design model — made of sturdy yet lightweight aluminum — provides steady support for different sized long guns ranging from semi-automatic and bolt action rifles to shotguns, carbines and pistols.